A Complete Guide to Digital Flow Meters

The need for precise process measurements usually requires processors turn to digital (rather than analog) instruments due to their accuracy, reliability, and ability to retain the measured results for analysis and data storage.

In the world of digital flow meters, there are a variety of technology options to choose from, which may make final selection difficult. We want to help!

This article will take a systematic look at the flow meters used in the sanitary processing industries.

- We'll start first with a definition of flow meters and outline for what purpose these instruments are used

- We'll briefly compare digital (i.e., electronic) and analog (i.e., mechanical) measuring devices in general and the advantages and disadvantages of each

- We'll walk through the types of digital flow meters on the market that are suitable for sanitary processing applications, explaining the operating principles behind each

- We'll end with a look at the digital flow meter products available from CSI

What is a Flow Meter?

Flow meters are used in the sanitary processing industries to measure the flow rate of fluids through pipes and tubes during production operations. Flow meters monitor both product flows and utilities flows (steam, water, glycol, etc.) in these types of plants.

Why measure fluid flow? There are a number of reasons.

- Measuring flow may be important in dosing operations, when a certain volume of liquid must be combined with a measured amount of a solid, such as when preparing a dough.

- Measuring fluid flow in either continuous or batch processing operations gives plant operators an indication of how productive their operation is at a point in time (i.e., how much product is being produced).

- In some cases, the products flowing through pipes may be subject to shear forces caused by flow velocity, which can impact the product's permeant structure, such as its rheology. Knowing the fluid flow rate in these cases is essential to maintaining product quality.

- In Clean-in-place (CIP) operations, a particular velocity of cleaning fluids through the pipes is a requirement for thorough cleaning. As a result, velocity must be measured to ensure that the CIP solution is doing its job.

Flow meters: digital or analog?

For any type of measurement, there are typically both analog and digital instruments that may be used. Let's look briefly at how each works, and their advantages and disadvantages.

Analog instruments are simple mechanical devices that translate the measurement of a material (such as a liquid or gas) onto some calibrated measurement indicator (such as an indicator needle on a dial).

For example, the ordinary thermometer is a type of analog measuring instrument. Heat warms the mercury in the storage bulb in the base of the thermometer, and it rises up a calibrated transparent tube in the device to measure how hot (or cold) the substance is.

The measurement process is purely a physical one. Digital instruments are more complicated.

A typical digital magnetic flow meter, also known as a magmeter, is one of the most common types of digital flow meters used in the sanitary processing industries, and is discussed in more detail in Section 4 of this article. As we explain in this section, digital flow meters rely on a number of different physical principles in their operation, including electromagnetic induction, the Coriolis effect, and ultrasonic wave propagation, depending on the type of meter.

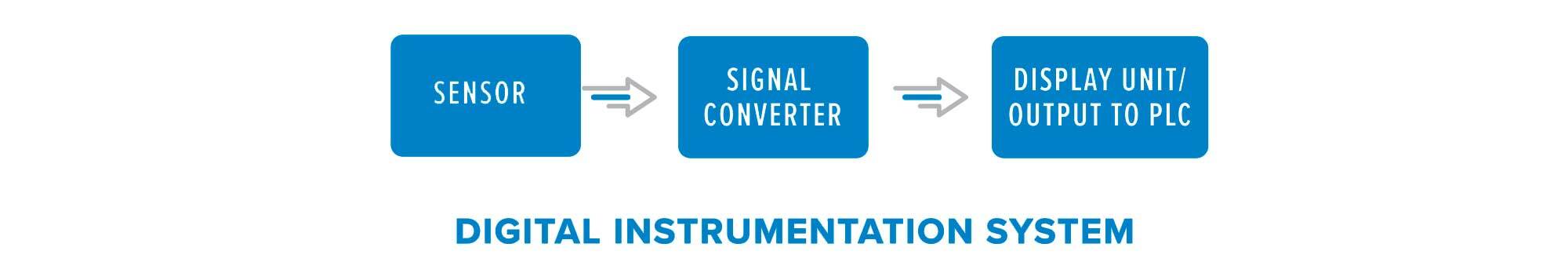

Digital instruments convert the characteristics of the material being measured — such as its heat, if a thermometer, or the flow rate of a liquid, if a flow meter — into an equivalent electrical form.

A component in the digital instrument called a transducer is responsible for making this conversion. The electrical information provided by the transducer then flows through various stages to provide the correct information.

- A signal processing unit — which amplifies the output from the transducer

- A multiplexer and signal converter — which mix the multiple analog signals provided by the processing unit

- An analog-to-digital converter — which converts the analog data into its equivalent digital form

- Into a display — which shows the actual quantity being measured into its digital form

Digital instruments are also designed to convert for factors, such as temperature, in the material being measured. See the figure below for a conceptual view of how these types of instruments work.

Analog instruments are simple, relatively inexpensive devices, and they typically perform well under adverse operating conditions (temperature, humidity, etc.). They are, however, intrinsically less accurate in their measurement than digital instruments.

Digital instruments, in contrast, are more complex and expensive, and more susceptible to adverse operating conditions than analog instruments (although protective cases for these devices can mitigate environmental issues). They are, however, more accurate in their measurement than analog instruments, and users may store the results of their measurements electronically for further analysis or the maintenance of operating records.

For measuring fluid flows in sanitary processing plants, digital flowmeters are the preferred choice.

Their electronics componentry and displays may be remotely located away from the fluid flow sensors to mitigate any environmental hazards in their operation. And, both the accuracy of the test results and the ability to collect and analyze data provided by digital flow meters are essential to maintaining both efficient operations and the quality of the products produced in these types of plants.

Common types of digital flow meters used in sanitary processing applications

Digital flow meters differ primarily in how their sensing mechanisms collect information on fluid velocity. However, the conversion of this information from an analog to a digital form occurs essentially the same way across all varieties of flow meters.

In the following paragraphs, we'll briefly describe the types of flow meters used most commonly in sanitary processing operations.

Magnetic flow meter

Also known as magmeters, magnetic flow meters determine fluid flow rates by measuring the voltage generated by a liquid as it passes through a magnetic field (see illustration).

The physical principle at work in this type of meter is called electromagnetic induction. Magmeters require a conducting fluid containing ions — for example, water — and an electrically isolated pipe surface — for example, a rubber lined steel tube — in order to function correctly.

Magmeters may be used to measure fluid velocity in a variety of fluids, including slurries and liquids containing embedded solids. However, the electrodes in this type of meter may be susceptible to corrosion when measuring certain liquids, resulting in inaccurate results.

To correct this, some magnetic flowmeters offer electrodes made from high nickel corrosive-resistant alloys.

Coriolis flow meter

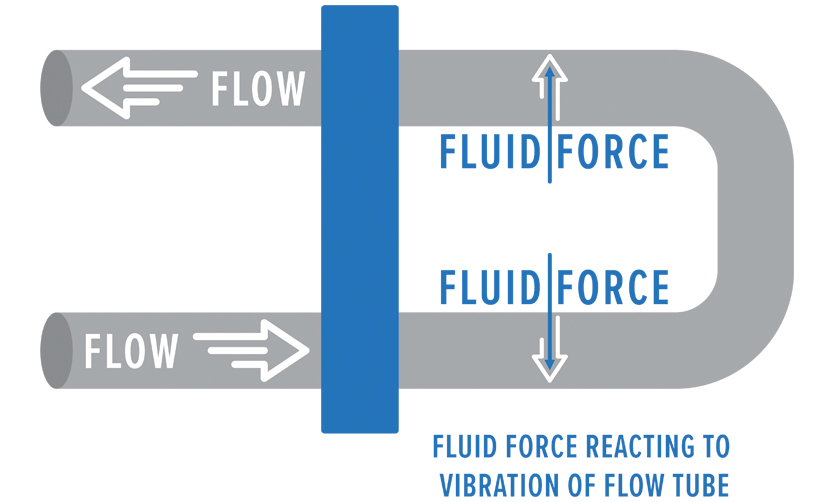

The highly specialized Coriolis digital flow meter uses a lateral tube that vibrates and distorts under fluid flow pressures. Sensors monitor and analyze the changes in frequency, phase shift, and amplitude of this vibration. The changes observed represent the mass flow and density of the fluid being measured (see illustration).

Flow measurement determined with a Coriolis-type meter is very accurate, irrespective of the nature of the gas or fluid being measured. However, a disadvantage in this type of meter is that the "U"-bend in the instrument causes it to be larger and heavier than other types of instruments, with potential concerns about drainability.

Mechanical flow meters

Mechanical flow meters are a family of devices where the measured fluid is mechanically displaced in the meter's body to measure fluid flow velocity. These devices consist of a chamber (or chambers) that obstruct the fluid flow and a rotating or reciprocating mechanism that allows the passage of fixed amounts of fluid through the chamber.

The rate of rotation or reciprocation of the measuring mechanism in the chamber (typically a screw, piston, gears, disk, rotating vane, or diaphragm) determines the flow velocity. See the illustration of a turbine-type mechanical flow meter.

Mechanical flow meters are typically very accurate. While some of these types of meters will tolerate some impurities in the measured fluid, this type of meter works best with clean and non-corrosive liquids. Mechanical flow meters also work well with some highly viscous fluids.

Ultrasonic flow meter

Ultrasonic flow meters measure the velocity of a fluid by using ultrasonic transducers to calculate flow volume. There are two main types of this variety of flow meter.

- Transit time flow meters measure the difference in the transit time of ultrasonic pulses propagating in and against the direction of fluid flow.

- Doppler flow meters measure the Doppler shift (i.e., the frequency shift) that reflects an ultrasonic beam off the particulates in the fluid flow.

The illustrations show, conceptually, how each type of ultrasonic flow meter works.

A significant advantage with these types of meters is that the measuring sensors remain outside the fluid flows, so they may be used with a wide variety of corrosive materials and slurries — so long at the speed of sound through the measured fluid is known).

Furthermore, ultrasonic flow meters are often inexpensive to use and maintain because they do not use moving parts, unlike mechanical flow meters.

Next Steps

The need for precise measurements usually requires professionals to turn to digital (rather than analog) instruments due to their accuracy, reliability, and ability to retain the measured results for analysis and data storage.

In the world of digital flow meters, there are a variety of technology options to choose from, including a few that meet the requirements for measuring fluid flow rates under sanitary operating conditions. For measuring fluid flows in product lines, either magnetic or Coriolis-type digital meters are good choices. For measuring fluid flows in utility lines carrying water, steam, etc., either magnetic or ultrasonic meters are suitable.

If you're confused by all the choices available, CSI can help. Call us at (417) 831-1411 to discuss your specific requirements for a digital flow meter.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.