Heat Exchanger Selection Criteria: How to Choose the Right One

With various heat exchanger designs on the market, selecting the most suitable heat exchanger design for transferring heat between fluids requires some knowledge of the differences between heat exchanger styles.

In this post, we discuss key characteristics of:

- Plate-and-Frame Heat Exchangers

- Shell-and-Tube Heat Exchangers

- Scraped-Surface Heat Exchangers

A key question in heat exchanger selection is always, “What type of heat exchanger does my process require?”

Process requirements come from fundamental properties of processed fluids such as viscosity and particulates. Processes also have thermal output requirements or amounts of heat that must transfer between fluids, and the temperature change that must occur by the end of the process.

When possible, using a plate heat exchanger is the right choice because they’re the most efficient and least expensive option. However, when fluids are highly viscous (thick) or include particulates, tubular exchangers can be more effective.

Scraped-surface heat exchangers are the most expensive option; they are also the most effective choice when fluids are incredibly thick or contain large particulates. Scraped-surface can be used for all products, but they are much higher in cost and lower in capacity.

Key characteristics of processed fluids

Heat transfer inside a heat exchanger results in temperature changes in both fluids, lowering the temperature of the warmer fluid and raising the temperature of the cooler fluid. Fluid properties partially determine the type of heat exchanger for the application.

Fluid types include:

- Water

- Oils

- Milk

- Cosmetics

- Pharmaceuticals

The choice of heat transfer medium is crucial as it affects the efficiency and design of the heat exchanger.

Thermal properties of fluids include:

- Temperature

- Acidity

- Flow rate

- Corrosiveness

- Viscosity

Plate heat exchangers handle low-to medium-viscosity fluids at higher flow rates than tube or scraped-surface models.

Corrosiveness of fluids is an important consideration because of their effects on heat exchanger components. Graphite is used for some industrial and pharma applications if the product is corrosive. When fluids have a high salt content, an even more corrosive resistant material like titanium is recommended for heat exchanger fabrication.

Manufacturers of heat exchangers typically ask for additional particulars about fluids before they can provide an accurate cost quotation, including:

- Heat load

- Temperature program

- Physical properties of liquids in question (if not a standard product such as milk, water, or beer, for example)

- Desired working pressure

- Maximum permitted pressure drop

- Available steam pressure

Consider phasing

Heat exchangers fall into two basic categories based on the fluids (liquids or gases) being processed.

- Single-phase heat exchangers process only one phase–liquid or gas

- Two-phase heat exchangers can be used to boil liquid into a gas. Such units are sometimes called boilers. They can also be used in condensing and evaporation applications.

In both single-phase and two-phase heat exchangers, the efficient flow of hot and cold fluids is essential for optimal heat transfer.

Units configured to cool gases so they condense into a liquid are called condensers.

Key design factors of heat exchangers

Some heat exchanger designs achieve higher heat-transfer rates and operate at higher temperatures than other designs. High heat transfer rates or specifications with close temperature approaches can include cooling cream to less than 40°F with 34°F and cooling beer wort with city water as far as possible to limit the load on the glycol chiller.

Size and shape are important factors as well because space limitations may dictate positioning and footprint requirements. Selecting the right heat exchanger model involves considering factors such as size, shape, and the specific requirements of the application.

Need for expandability: if a need to expand or contract heat transfer capacity is likely, plate heat exchangers are an excellent choice because you can change capacity easily by adding or removing plates.

Considerations when selecting a heat exchanger

The table below outlines several considerations to weigh when selecting a heat exchanger.

| Characteristics | Plate-and-Frame | Shell-and-Tube | Scraped-Surface |

|---|---|---|---|

| Cost Per Square Foot | Low | Low | HIgh |

| Laminar | Low | Low | Medium/HIgh |

| Turbulent | High | Medium | Medium |

| Amount of Regeneration | High | Medium | None |

| Maintenance Cost | Medium | Low | High |

| Operating Pressure | Low | High | High |

| Use With Particulates | Poor | Good/Excellent | Excellent |

| CIP Ability | Excellent | Excellent | Good |

| Materials of Construction Available | Good | Good | Good |

| Residence Time | Low | Medium | Medium |

| Length of Time | Medium/Good | Medium/Good | Excellence |

| Flexibility of Process | Fair | Good | Good |

When to choose a Plate-and-frame heat exchanger

In this section, we compare shell-and-tube with plate-and-frame heat exchangers based on:

- Energy use

- Footprint

- Ease of maintenance

- Capacity adjustment

- Capital expense

When considering a plate-and-frame heat exchanger, a gasketed plate heat exchanger is often the preferred choice due to its efficiency and ease of maintenance.

1. Energy use

Plate heat exchangers are up to five times more efficient than shell-and-tube designs. In many cases, you can recover more heat by replacing existing shell-and-tube models with compact heat exchangers.

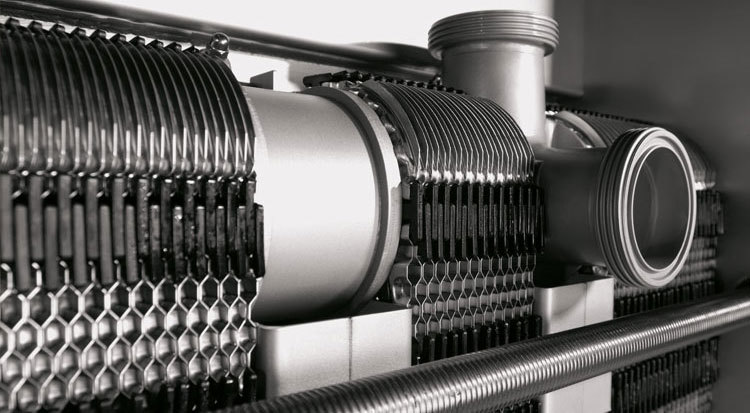

The series of plates in a plate-and-frame heat exchanger creates gasketed spaces between plates. These spaces alternate between two fluids—one hot and one cold. The design delivers very high heat transfer efficiency because the plates create a surface area that's much larger than shell-and-tube designs that would fit in the same space.

2. Footprint

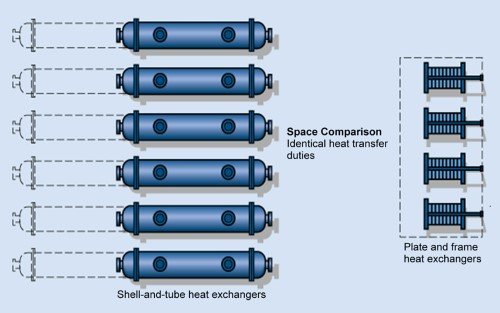

Shell-and-tube heat exchangers require more floor space than plate heat exchangers, as the comparison on the left illustrates.

3. Ease of maintenance

High-quality plate-and-frame heat exchangers can operate efficiently for many years without maintenance. Plates are easy to access for inspection or cleaning. Cleaning intervals depend on amounts of fouling or scaling.

ou can easily remove plates for cleaning or repair, whereas shell-and-tube models are more labor-intensive.

Sludge or scale coating on surfaces reduces the heat exchanger's thermal efficiency. Because of plate and frame exchangers' smaller, modular design, they are faster and easier to clean than larger shell-and-tube units.

4. Capacity adjustment

Plate heat exchangers make capacity adjustment relatively easy. Plates are easy to access, add, and remove. In contrast, shell-and-tube units have fixed capacity at the time of installation.

5. Capital expense

Cost of ownership is always a critical factor in the decision-making process. A plate heat exchanger is the lowest cost option because it can achieve high heat transfer coefficients — with pure counter current flow — giving the most efficient heat transfer and lowest surface area. Maintenance cost is also reasonably low, especially compared to scraped-surface heat exchangers. The main expense is the replacement of gaskets and, occasionally, of plates.

The close temperature approach, meaning a cold fluid being heated to a temperature that is very close to the temperature of the entering hot fluid, allows more regeneration and heat recovery, making a plate heat exchanger a good option. The compact size of a plate heat exchanger is also important to applications with tight spaces.

One key advantage of plate heat exchangers is their modularity. Installers can assemble or disassemble plate heat exchanger units onsite. These units have about 6% the weight of comparable shell-and-tube units while taking up about 10% of the floor space.

In addition to the capital expense for the equipment, capital costs can include:

- Shipping

- Handling

- Installation

- Maintenance over the unit's lifetime

To improve energy efficiency, using a smaller heat exchanger to meet existing requirements translates into savings in transportation and installation.

When to choose a shell-and-tube heat exchanger

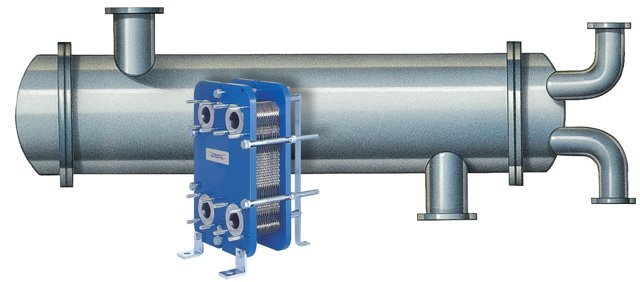

The basic shell-and-tube principle moves product through a bundle of parallel tubes with heating fluid between and around the tubes.

Fluid flowing inside the tubes is called tube-side fluid; fluid flowing on the outside of the tubes is called shell-side fluid. The tube-side fluid is separated from the shell-side fluid by tube sheets.

In applications where the two fluids flow at different pressures, the higher-pressure fluid typically flows through tubes, and lower-pressure fluid flows on the shell side.

The reason is cost: high-pressure tubes are less expensive than high-pressure shells.

Because of the larger clearances between shell-and-tubes than plates in plate heat exchangers, the shell-and-tube design is a good choice for fluids that contain particulates — such as pulpy juices.

Because shell-and-tube heat exchangers consist of a large pressure-vessel shell with tube bundles inside, they can conduct heat transfer under higher pressure than some other designs.

Fouling

Another advantage of shell-and-tube designs is a lower potential for the fluids you're processing to foul the equipment. Fouling of heat exchangers is the accumulation of deposits from fluids that pass over or through heat transfer surfaces.

The fouling issue comes down to the impact of fouling on exchanger performance and how easily you can clean the equipment.

If the shell side is the right option for running a high-fouling liquid, adding baffles to the tube may be an effective way to increase turbulence and reduce opportunities for particles to stick to the inside of the shell or the outside of tubes.

Fouling in heat exchangers occurs for several reasons:

- Crystallization: This is caused by salts that dissolve and crystalize upon cooling. Consider shell-and-tube designs for fluids with high salt content subject to high-temperature changes.

- Sedimentation, or deposits of sand, rust, or other compounds: Sedimentation comes from corrosion products, metal oxides, silt, alumina, and diatomic organisms (microalgae) and their excrement. Velocity adjustments can be made in some cases to reduce the impact of sedimentation.

- Corrosion: Fouling due to corrosion can affect the heat-transfer performance of equipment, so consider the properties of heat exchanger materials and fluids to avoid corrosion when possible. To learn more, read How To Clean and Maintain Your Heat Exchanger.

- Incrustation: the accumulation of a crust or coating of processed fluids, minerals, or cleaning agents on the surface of heat exchanger parts.

- Scaling: a type of incrustation caused by calcium carbonate, calcium sulfate, and silicates.

- Biological growth: Sources of biological fouling include bacteria, nematodes, and protozoa.

When to choose a scraped-surface heat exchanger

Some processes require heat transfer that prevents fouling from viscous and sticky products. In those processes, scraped-surface heat exchangers are a type of liquid heat exchangers that are particularly effective for processing viscous and particulate-laden fluids. Scraped-surface heat exchangers are the right choice because of their ability to process fluids that include a high number of particulates or high viscosity.

Using scraped-surface designs can assist processors in moving from batch to continuous processing. While batch processing may be required in pharmaceutical processing to meet safety and purity requirements, continuous flow processing is often preferable in food processing due to its potential for reducing waste and improving productivity.

In addition, scraped-surface heat exchangers can do phase changes (for products such as ice cream) and evaporation to cook and concentrate products such as sauces.

Applications for scraped-surface heat exchangers

- Baby Food

- Bread Dough

- Chocolate Spreads

- Fruit Pie Fillings

- Gelatine

- Gravies

- Hummus

- Ketchup

- Licorice

- Mayonnaise

- Mechanically Deboned Meat

- Nougat

- Peanut Butter

- Pizza Sauces

- Puddings

- Salad Dressings

- Salsa and Taco Fillings

- Sandwich Spreads

- Sauces

- Shampoos

- Skin Lotions

- Whipped/Aerated Products

Making Your Selection

To help with the model-selection process, manufacturers typically provide comparison charts like the one below.

Heat exchanger | Average gap (mm) | Particle size (mm) | Fiber length (mm) | Pulp % | Viscosity CPS |

Plate-and-Frame | |||||

Typical industrial plate | 2.4-3.95 | Dia 0.5 | 1 | 2 | 2500 |

Typical sanitary plate | 3.95 | Dia 0.5 | 1 | 3 | 5000 |

Low contact point plate | 3.95 | Dia 0.5 | 5 | 7 | 1000 |

Shell-and-Tube | |||||

Monotube | Pipes dia 14-97.6 | Dia 12-95 | Up to 50 mm | No limit | 1000 |

Multitube | Pipes dia 12-22.6 id | Dia 5-10 | Up to 18 mm | 60 | 1200 |

Annular space | GAP 5-49 mm | Dia 3-47 | Up to 35 mm | 80 | 12000 |

Scraped-Surface | Up to 31 mm | No limit | No limit |

Guide to Choosing the Right Heat Exchanger

This guide is designed for processors, production managers, and mechanical engineers to help in the heat exchanger selection process.

Next Steps

With various heat exchanger designs on the market, selecting the most suitable design for transferring heat between fluids can be difficult.

We're here to help! Whether you need parts to keep your current units operating, a direct replacement for a worn out or inefficient heat exchanger, or a new unit for a new process, CSI can support you.

To learn how we can help, contact us today!

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.