How Return Pumps Are Used During Clean-In-Place

Return pump size

The return pump should be sized to quickly remove the used solution from the process lines at a rate of approximately 10% greater than the supply pump. Return pumps are typically sanitary stainless steel centrifugal or liquid ring pumps with cleanable seals that are compatible with the system’s product soil and cleaning chemicals.

Differences between return pumps and supply pumps

A difference between return pumps and supply pumps is the need for self-priming in return pumps to avoid cavitation and air locks.

Cavitation is the formation of small vapor-filled bubbles in fluids, commonly caused in pump fluid chambers when pressure in the chamber drops below the vapor pressure of the fluid.

The bubbles then implode when re-exposed to high pressure. The implosions sound like gravel scraping along the impeller, casing, and through pipes, and the force of the implosions is strong enough to damage system components.

Air lock is the restriction or stoppage of liquid flow caused by vapor that collects at a high point in a fluid-filled piping system or in centrifugal pumps. The vapor is less dense than the fluid, so it rises to high points in the system where blocks occur. Air locks can damage pump seals. If a pump airlocks during a CIP return cycle, it will cause the tanks to backup and fill with CIP solutions. This could cause the tank not to come clean and could result in the CIP system using additional chemicals and water.

Cavitation in return CIP circuits

The imploding bubbles from cavitation also cause strong vibrations, loss of efficiency and, over time, damage to components. Designed to prevent cavitation problems, self-priming (SP) centrifugal pumps can reach a fully-primed pumping condition even when air is mixed with water, and are therefore the most effective pumps for CIP return applications.

Leaving cavitation untreated can lead to several problems:

- Decreased flow and/or pressure

- Excessive power consumption

- Impeller damage

- Excessive vibration causing seal and bearing failure

- Pump housing failure

Key causes of cavitation

Because of the severity of cavitation problem, understanding the key causes of cavitation in CIP systems is the most cost-effective strategy for preventing damage.

- Rapid drop in suction pressure at the return pump

- Poor flow conditions in the system

- Uneven increase in liquid temperature

Rapid drop in suction pressure at the return pump

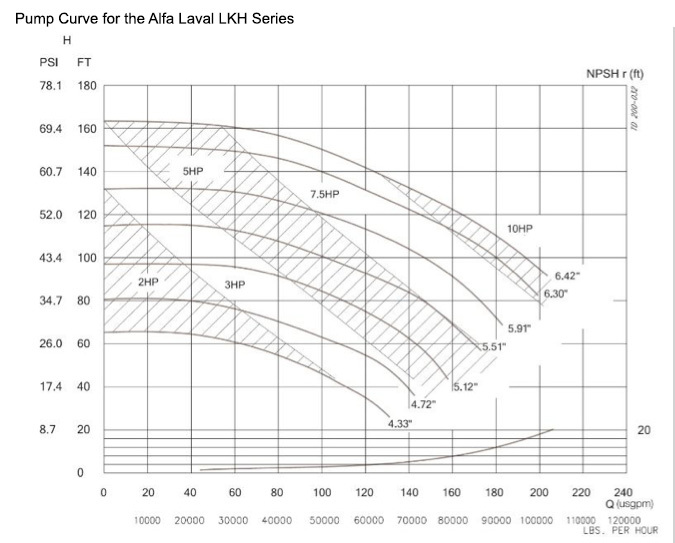

The fluid pressure at the inlet of the pump needs to be above the liquid vapor pressure. Return pump pressure ratings are indicated by their pump curves in measures called Net Positive Suction Head Required (NPSHr).

The NPSHr rating for a pump indicates the minimum amount of pressure required on the suction side of a pump to avoid cavitation. NPSHa must always be greater than NPSHr. When available pressure falls below required pressure, cavitation occurs.

Poor flow conditions

Valve obstructions or sharp turns in piping may also lead to drops in available pressure that lead to cavitation.

Uneven increase of the pumped liquid temperature

If the CIP fluid temperature rises unevenly, vapor pressure increases, which causes the available pressure to fall, causing cavitation.

Pump performance curves

The most important link between a specific CIP application and proper pump selection is manufacturers’ pump performance curve, which accurately predicts how a particular pump will perform under different head conditions.

Pump curves include the performance data you need to begin sizing your pump:

- Pump model

- Pump speed

- Connection sizes

- Impeller size range

- Head range

- Flow range

- Power requirement

- Efficiency

- NPSHr

Two pressure considerations impact a return pump’s performance: inlet pressure and discharge pressure. Both must be considered to establish system requirements.

- Inlet Pressure – the absolute pressure of the fluid as it enters the pump. Insufficient fluid pressure at the inlet of the pump can cause cavitation

- Discharge Pressure – the pressure of the fluid as it leaves the pump. The discharge pressure of the pump must be sufficient to overcome the resistance (head) created by the piping system downstream from the pump. Determine system head by calculating the vertical distance the fluid must travel, the friction losses created by the fluid traveling through the piping, and the specific gravity of the fluid.

With performance curves and pump sizing software, a pump system partner can determine the best efficiency point (BEP) and optimum pump choice by application.

To meet CIP requirements for return circuits, use self-priming air-screw, liquid-ring, or twin-screw pumps

Self-priming air-screw and liquid-ring pumps

Self-priming air-screw and liquid-ring pumps are designed in a way to handle fluids that contain entrained air. Air-screw pumps do this by including a recirculation pipe that maintains a continuous liquid ring around the pump’s air screw.

Self-priming pumps are efficient at emptying tanks and drums, and they are capable of handling shear sensitive products due to their tight manufacturing tolerances and impeller shape.

Because self-priming pumps can move water/air mixtures without vapor locking, they are able to evacuate tanks completely. Return pumps can also pull foam and solution from lines.

Self-priming pumps made by most top-quality manufacturers are 3-A compliant with available hygienic options such as casing drains and better surface finishes for internal surfaces.

Advantages

- Highly effective as a CIP return pump

- Excellent for pumping fluids containing air or gases

- Capable of superior suction lift

- Self-priming once the casing is half-filled

- Minimal maintenance required

Disadvantages

Not recommended for high viscosity fluids

Typically not available with high-purity options for product handling applications

Low capacity output compared to other standard centrifugal pumps

Twin screw pumps

Twin screw pumps conforming to 3-A Sanitary Standards can serve several CIP return applications. Their unique design allows the pump to perform both processing and CIP using the same unit. Some models can move soft solids delicately, without damaging the product or compromising visual integrity.

Twin screw pumps are typically self-priming and have a low net positive suction head (NPSHr) for tank emptying. Some models handle up to 60% of entrained air, reducing cavitation and allowing for constant gentle product flow even at high speeds.

Advantages

- Wide range of flows and pressures

- Wide range of liquids and viscosities

- High tolerance for entrained air

Disadvantages

Higher cost because of precise tolerances

Power requirement may be significantly higher

Additional maintenance requirements

Tip For Removing Air Without Leaking Product

In places where a standard centrifugal pump is already in place, an Air Eliminator could be added upstream of the inlet of the pump to help prevent it from airlock by giving a path for the air to escape from the system.

Pump maintenance and repair

Industry professionals have long recognized that a well-documented preventative pump maintenance program provides a company with significant cost savings. Maintenance costs may amount to as much as 35% of total production costs. Downtime naturally lowers production levels, but quality often suffers too. Machines do not perform properly when they are out of factory tolerance.

Preventative maintenance programs help prevent costs from three main sources:

- Overtime pay to get production back on track

- Special-ordered parts during emergencies

- Rush order costs

A maintenance management program reduces downtime, improves reliability, monitors unit performance, and helps diagnose equipment problems before they cause failure.

Planned maintenance is proactive instead of reactive. It helps minimize equipment damage and extends the life of process systems, increasing the return on investment on equipment.

A safe food preventative maintenance program should include at a minimum:

- A list of equipment requiring preventative maintenance procedures

- A schedule for preventative maintenance

- Documentation for preventative maintenance and work instructions

- Original equipment manufacturer (OEM) parts

- Procedure for equipment turnover

Thorough preventative maintenance records are part of compliance requirements for Hazard Analysis Critical Control Point (HACCP) programs and the Food Safety Modernization Act’s (FSMA) Hazard Analysis and Risk-based Preventive Controls (HARPC) provision.

Maintenance records give management a tool to do just that, as well as allowing them to better judge equipment reliability and return on investment (ROI).

Outsourcing services is a practical solution when an organization is short on resources. Outside professionals have the training, equipment, and reporting systems already in place, making it easy to integrate into an existing structure. Industry leaders that specialize in sanitary hygienic processing systems can offer reliable solutions for valve, pump, and homogenizer services. All preventative maintenance service programs are customizable, allowing a company to outsource what is needed, while keeping other procedures in-house.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.

A Guide to Choosing the Right Pump for Hygienic Applications

This guide is intended for engineers, production managers, or anyone concerned with proper pump selection for pharmaceutical, biotechnology, and other ultra-clean applications.