A Complete Guide to Sight Glasses

Sight glasses are critical instruments used in the process industries to determine the condition and level of fluids and media in both tanks and pipelines.

This article will provide an overview of sight glasses, a specialized type of instrument used in various processing industries, including pharmaceuticals manufacturing; food & beverage processing; semiconductor manufacturing; utilities; energy production; oil and gas production; and wastewater treatment and management.

Within these industries, sight glasses find their way into a variety of processing components, including fluid and gas handling pipes as well as tanks and vessels.

In this article we will discuss:

- What is a sight glass

- The different types of sight glasses

- Considerations to take when selecting the right type of sight glass for a particular application

What is a Sight Glass?

A sight glass — which is also called a sight window or view port — is a transparent window that provides a means of seeing inside a process pipe or tank.

Processing plant operators use sight glasses to:

- Verify the production stages of a process visually

- Inspect media or fluids for changes in color or consistency

- Observe the liquid levels in a tank

There is also a specialized type of sight glass called a sight flow indicator — also known as a sight glass tube. Sight flow indicators are transparent tubes installed in pipes to provide a visual means of verifying the flow direction and flow rate of fluids; and inspect products or media flowing through process lines.

Sight glasses have been in use in the industry for a long time. One of the earliest applications for these instruments was as water level gauges in the boilers of steam-powered locomotive engines, where they were used to ensure that water was kept at a specified level to maintain safe operations.

In the sanitary processing industries, sight glasses are primarily used in one of two ways.

- In the biopharmaceutical industry, manufacturers use sight glasses installed in tanks and vessels to verify the various steps of fermentation in a process.

- In the food & beverage processing industry, sight glasses are used to check product clarity and cleanliness; to confirm that changeover has occurred in a process; and for general visual inspection of fluids and slurries.

Types of Sight Glasses

There are two primary varieties of window or port-type sight glasses.

- A simple window sight glass assembly consists of a glass disc sandwiched between two gasketed metal rings. This type of sight glass may be disassembled for easy cleaning and is suitable for low-pressure and non-critical processes

- For high-performance applications, a fused sight glass instrument is the industry standard. In this type of sight glass, the window is fused to the metal carrier ring during its construction.

With fused sight glass windows, the compressive force of the metal ring exceeds the tensile strength of the glass, and as a result, these types of sight glasses are highly resistant to catastrophic failure.

Fused sight glass windows offer both high pressure and high safety margins in operation.

What Are Sight Glasses Made Of?

Various types of glass materials are used in constructing sight glasses.

1. For low-pressure, non-critical applications in which the fluid or media being observed is both low in temperature and non-abrasive, sight glass windows may be made from standard soda lime glass.

This type of glass, though, will crack at higher temperatures, so for process fluids up to 536°F, borosilicate glass (trade name Pyrex®) or acrylic plastics are the standard materials used to construct sight glass windows.

2. Above 536°F, sight glass windows are constructed from quartz or sapphire glass.

Note that sight glasses in this latter category are commonly used for high temperature processing applications in excess of 500°F or where process need more thermal shock or corrosion resistance.

3. For some sanitary processing applications, sight glasses may also be made from high-grade specialty plastics such as acrylic or polycarbonates.

In comparison to sight glasses or view ports made from glass, plastic sight glasses offer a number of advantages:

Advantages of Plastic Sight Glasses

- Unlike many types of glass, plastics are generally shatter-proof. This is an important feature, as toughness is a critical safety issue. Indeed, some processors or manufacturers will not allow glass or other shatter-prone materials in their process lines due to a concern for the safety of their workers or customers.

- Plastic sight glasses are chemically resistant to the acids, alkalis, and alcohols commonly found in many food and beverage processing applications in particular.

- Depending on how they’re made, plastic sight glasses may be very robust alternatives to glass. Some manufacturers offer plastic sight glass windows formed by injecting the plastic polymer into a precisely formed metal support ring, resulting in an extremely strong final product.

- Compared to glass sight glasses, plastic sight glasses or viewports are also relatively inexpensive to make. As a result, they often find their way into low-end uses such as fluid level indicators.

- Unlike glass viewports, plastic viewports or sight glasses may be formed into several different types of shapes. The sight glass window may be domed for easier viewing of the contents inside the pipe or tank, or the plastic sight glass may be cast as a one-piece transparent unit to be threaded into a process pipe or tank for use as a viewing port. See the examples below.

Disadvantages of Plastic Sight Glasses

- Compared to glass, plastic sight glasses have a more restricted operating range. Even high-grade plastic composites will melt at higher operating temperatures, so these types of sight glasses are only suited for use in lower-temperatures applications below 300°F.

- Relative to glass versions, plastic sight glasses are more prone to abrasive damage, scaling, and other surface inclusions that over time may affect the transparency and functionality of the sight glass.

Things to Consider When Determining the Best Sight Glass For Your Application

When figuring out what type of sight glass is best for a particular application, the following factors must be kept in mind:

1. Maximum operating temperature

As noted above, standard soda lime sight glass windows or plastic view ports are only suitable for operating temperatures of 300°F or less.

Above that temperature range, borosilicate glass or quartz/sapphire glass must be used.

2. Thermal shock

Sight glass engineers need to take rapid temperature changes into account when choosing what type of material to use in a sight glass.

Sight glass that has a high thermal expansion coefficient, low thermal conductivity, and low durability is not suited for working environments that feature rapid or extreme fluctuations in temperature.

For this reason, borosilicate glass—with a lower coefficient of expansion than standard glass—is more tolerant of temperature changes, and is the preferred material for glass windows. Plastic sight glass windows will generally tolerate temperature changes well due to the elasticity of the material.

3. Corrosion

Some caustic or acidic fluids will cause sight glass windows to become “cloudy” over time, hindering their transparency. In applications subject to these conditions, choose a sight glass window material (either glass or plastic) that’s less susceptible to corrosive influences.

Also, choose a sight glass frame material that’s compatible with the fluid being observed, and corrosion resistant as well. Since many types of metals can be attacked by process fluids, stainless steel compounds of various types are the preferred frame material.

4. Abrasion

Choose a sight glass material that’s not affected by particulates in the fluid being observed, which over time may abrade or erode the sight glass. Sight glasses can be inspected visually or with the aid of ultrasonic equipment to check for abrasions.

5. Pressure

As mentioned earlier, fused-type sight glasses (or cast-type plastic windows) should be used in all high-pressure applications to avoid sight glass failure.

6. Impact

In some applications, such as food processing, materials entrained in process fluids may impact against the sight glass window. Replace sight glasses immediately if scratches are seen from particulate impact.

Fixed-type sight glasses provide the greatest resistance to impact damage if the viewing window is made from glass.

Sight glass products offered by CSI

CSI is proud to offer sight glasses manufactured by Stainless Products (SPI).

SPI sight glasses are specifically engineered for the hygienic processing industries, and are offered in several configurations that allow processes to be maintained without exposure to the external environment:

- In-line and cross-type sight glasses are useful for monitoring changes in color or consistency when transferring products.

- Tank sight glasses allow for fermentation and other processes to be monitored in the midst of an operation.

These sight glasses are often installed as semi-permanent components in a variety of tanks.

All SPI sight glasses are 3-A certified and come apart for easy cleaning. Tri-clamp end connections and borosilicate glass viewports come standard with all models (weld, bevel seat, and John Perry connections are available as options).

Temperature and pressure ratings vary with the gasket and clamp union selection. Common end use applications include processed foods, dairy, beverages, brewery, home and personal care products, and biotech/biopharmaceutical manufacturing.

SPI offers the following sight glass models:

SP56

Full 360° view of process media. Well suited for vertical and horizontal mounting. When mounting in a horizontal position no mechanical force should be exerted on the glass. Viton® elastomer included.

| Size

(in) | A (3 in. Glass) | A (6 in. Glass) |

|---|---|---|

| 1½ | 6.50 | 9.50 |

| 2 | 6.50 | 9.50 |

| 2½ | 6.50 | 9.50 |

| 3 | 6.50 | 9.50 |

SP-54

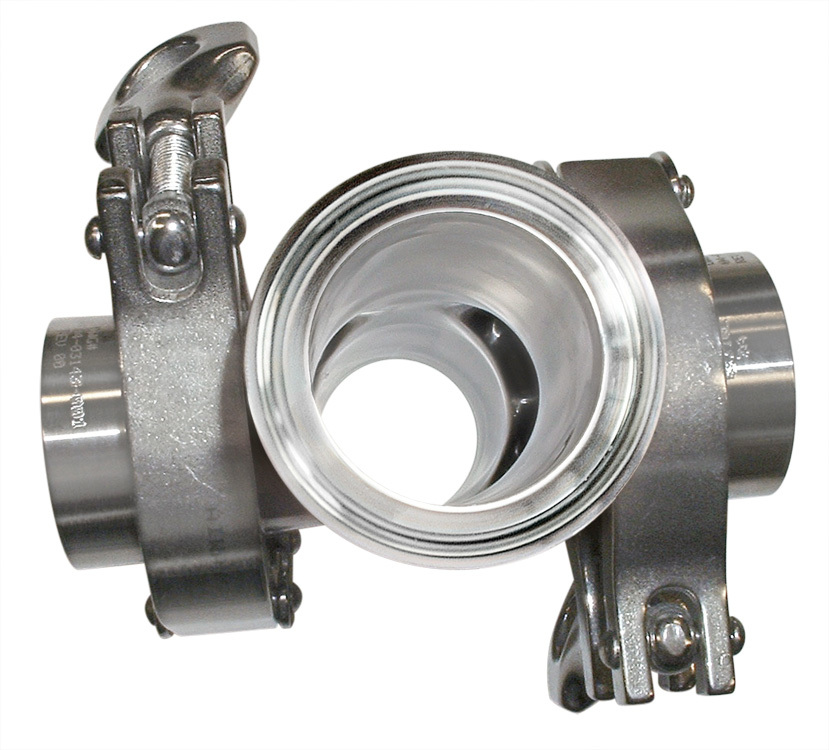

Cross style sight glass that provides a view inside of the production flow. Elastomer options include: Viton®, Buna, EPDM, and PTFE.

| Size (in) | A (in) | B (in) |

|---|---|---|

| 1½ | 4.50 | 5.50 |

| 2 | 4.75 | 7.00 |

| 2½ | 5.25 | 7.00 |

| 3 | 5.75 | 7.50 |

| 4 | 7.25 | 9.00 |

SP54SW

Compact unit with easy disassembly. Commonly used in vessels. Elastomer options include: Viton®, Buna, EPDM, and PTFE.

| Size (in) | A (in) |

|---|---|

| 1½ | 1.25 |

| 2 | 1.25 |

| 2½ | 1.25 |

| 3 | 1.25 |

| 4 | 1.25 |

Next Steps

Sight glasses are critical instruments used in the process industries to determine the condition and level of fluids and media in both tanks and pipelines.

As shown in this article, there are several different types of sight glasses, and selecting the proper one for a particular application is based on a number of factors.

CSI can help you in selecting the proper sight glass for your application. Contact us at (417) 831-1411 to further discuss your requirements.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.