Alfa Laval GJ 10

The Alfa Laval GJ 10 is the only automated tank cleaning machine capable of getting all residual fuel, dirt, and sludge out of underground storage tanks (UST). Designed to fit through standard UST inlets, the new lightweight unit is fluid driven and requires no external power supply to clean any size storage tank. Its powerful 360° rotary jets blast away contaminants and breaks up dirt and sludge that can be conveniently vacuumed away.

The GJ 10 is the only machine small enough to fit into USTs with enough power to clean all of the interior. It easily puts the contaminant-laden sludge into solution that allows for complete liquid extraction and thorough tank cleaning. Using a GJ tank cleaning machine, tanks can be quickly cleaned and ready to accommodate the next load without the risk of contamination. Responding to the needs of the petroleum and contract cleaning industries, the GJ 10 tank cleaning machine was designed to be the most effective way to fully clean fuel storage tanks.

Application

The Alfa Laval GJ 10 tank cleaning device fits through a four inch opening and is capable of cleaning a 30,000 gallon underground fuel storage tank with one insertion. This device blasts away contaminants and breaks up dirt and sludge in minutes. The Alfa Laval GJ 10 easily converts the contaminant-laden sludge into a solution which allows for complete liquid extraction and thorough tank cleaning. The device is part of the world-renowned Gamajet range of tank cleaning devices.

Working Principle

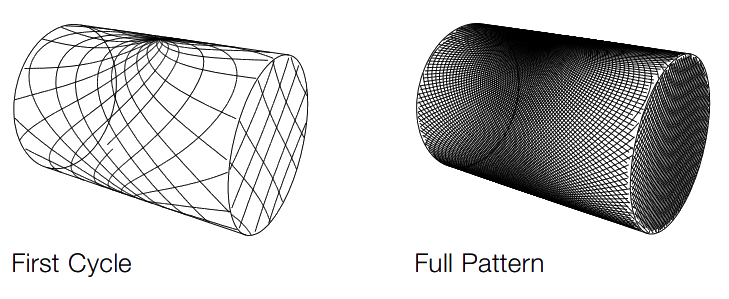

The Gamajet range of high impact tank cleaning devices combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point at which the concentrated stream impacts the surface. It is this impact and the tangential force that radiates from that point which blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the device is engineered to rotate in a precise, repeatable and reliable, 360° pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time.

STANDARD DESIGN

The choice of nozzle diameters can optimize jet impact length and flow rate at the desired pressure. As standard documentation, the Alfa Laval GJ 10 can be supplied with a “Declaration of Conformity” for material specifications.

OPTIONS

Electronic rotation sensor to verify 3-D coverage.

Caution: Do not use for gas evacuation or air dispersion.

CLEANING PATTERN

Technical Data

| Lubricant | Food grade |

| Throw Length (max) | 35 ft |

| Working Pressure | 50 - 750 psi |

| Working Temperature (max) | 250°F |

| Weight | 9.5 lb |

| Connections | 1.5 inch NPT |

| Materials | 316L, PPS, FKM (EPDM and FFKM available) 2.1 material certificate |

Dimensional Data

| A (in) | 10.7 |

| B (in) | 8.0 |

| C (in) | 3.7 |

| D (in) | 1.7 |

| E (in) | 3.9 |

| F (in) | 3.9 |

| G (in) | 5.4 |

Flow Rate

Impact Throw Length

Cleaning Time

Product Resources

See all resources by Alfa LavalLiterature

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

It only takes a minute.

Sign in

Sign in to save resource to your dashboard.

Literature for GJ 10 have been saved to your dashboard!

Literature for GJ 10 are already in your dashboard.